—— VCU Hardware-in-the-loop (HIL) Test System

The vehicle controller (VCU) is the core component of a new energy vehicle. The performance of the VCU controller directly affects the power, safety and economy of the vehicle. The VCU hardware-in-the-loop (HIL) simulation test system can effectively solve the needs of the VCU test phase.

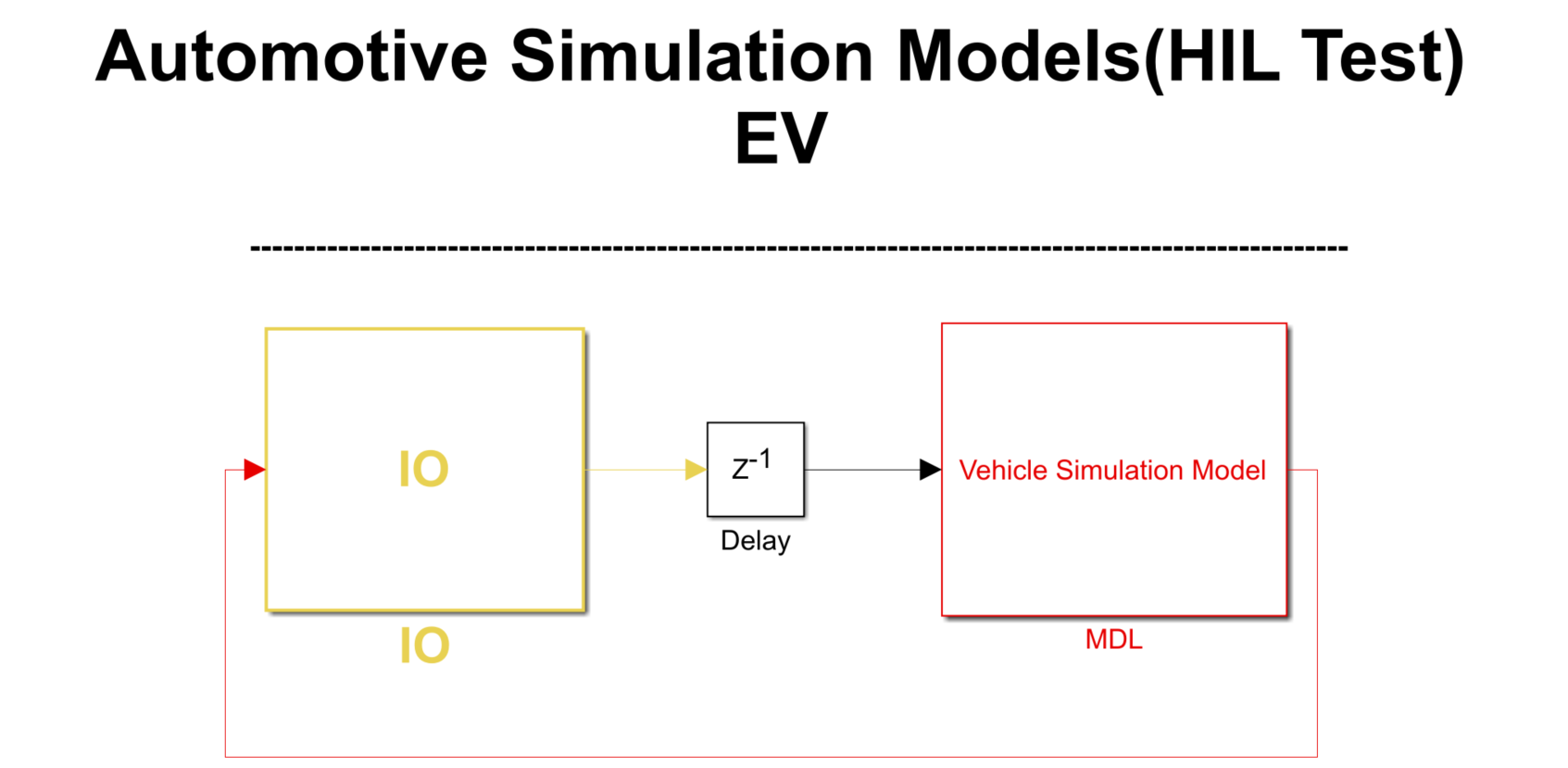

HIL (Hardware-in-the-Loop) hardware-in-the-loop test system is a real-time simulation model running in a real-time processor to simulate the operating state of the controlled object, and connects with the electrical control system under test through the I/O interface. Test the VCU controller for comprehensive and systematic testing.

Through the HIL test system, the VCU controller and the real-time system form a virtual controller test environment. The test tools and corresponding test cases are used to test various functions and working conditions of the vehicle VCU controller, and various hardware failures can also be simulated. , And finally generate a test report.

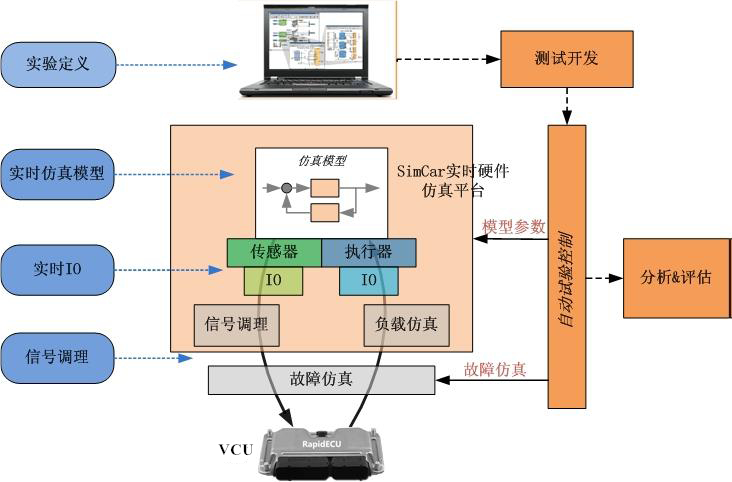

Principle of VCU-HIL test

Principle of VCU-HIL test

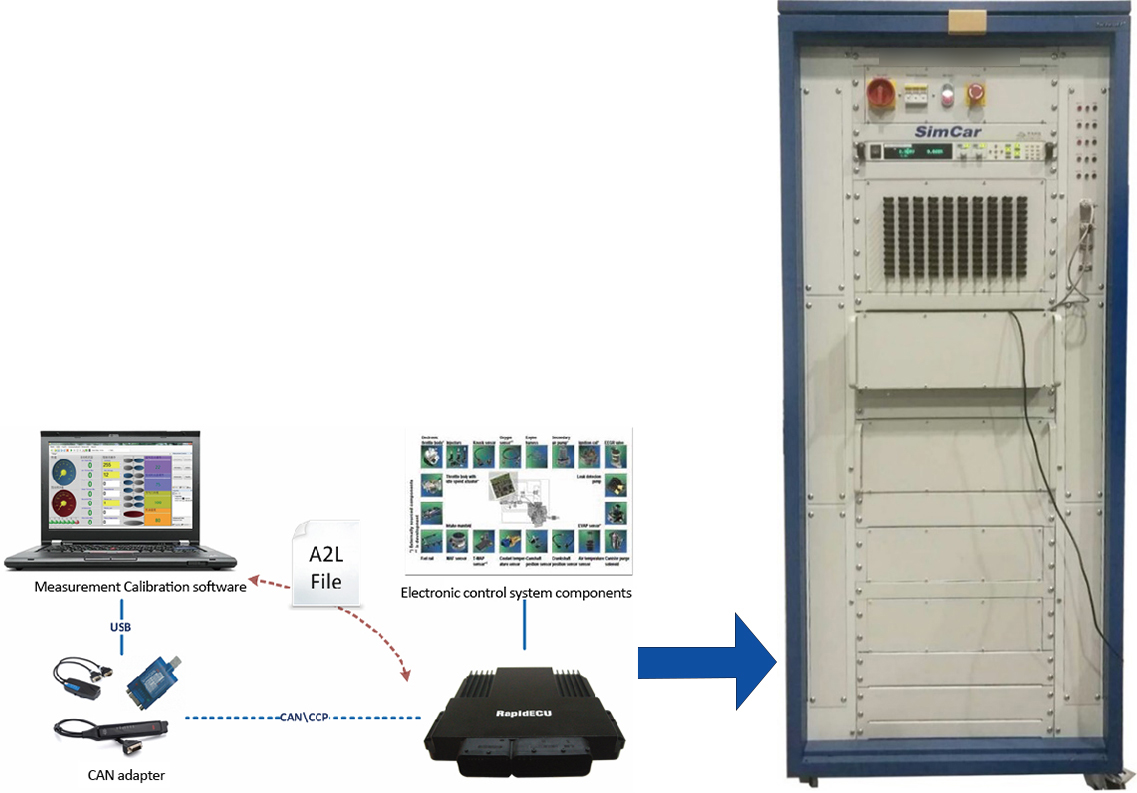

The SimCar hardware-in-the-loop test system is a test platform provided by Huahai Technology's foreign partners with test services. It is a complete set of hardware-in-the-loop simulation test equipment for testing the functions, system integration and communication of the electronic control unit. The biggest feature of SimCar: It can be combined with our RapidECU rapid prototyping tool for rapid development of control algorithms, HIL testing and parameter calibration.

SimCar hardware-in-the-loop test system

SimCar hardware-in-the-loop test system

—— Main Function

• VCU control function test

• Extreme conditions test

• Calibration of control parameters

• Bus network test

• Regression Testing

• Endurance test

• Fault diagnosis and response function test

—— VCU-HIL System Framework

• Hardware simulation platform: Provide a real-time simulation environment that meets the real-time operation of the vehicle model; simulate all input signals required for the normal operation of the controller, and collect the control commands issued by the controller;

• Real-time simulation model: Simulate the physical behavior of each system of the vehicle. In order to realize various driving conditions of the virtual vehicle, the simulation model also includes the driver and road environment model;

• Test management software: used to build and configure HIL test software engineering, real-time monitoring of the test process and online parameter adjustment;

• Automatic test software: realize automatic test through automatic test software and generate test report.

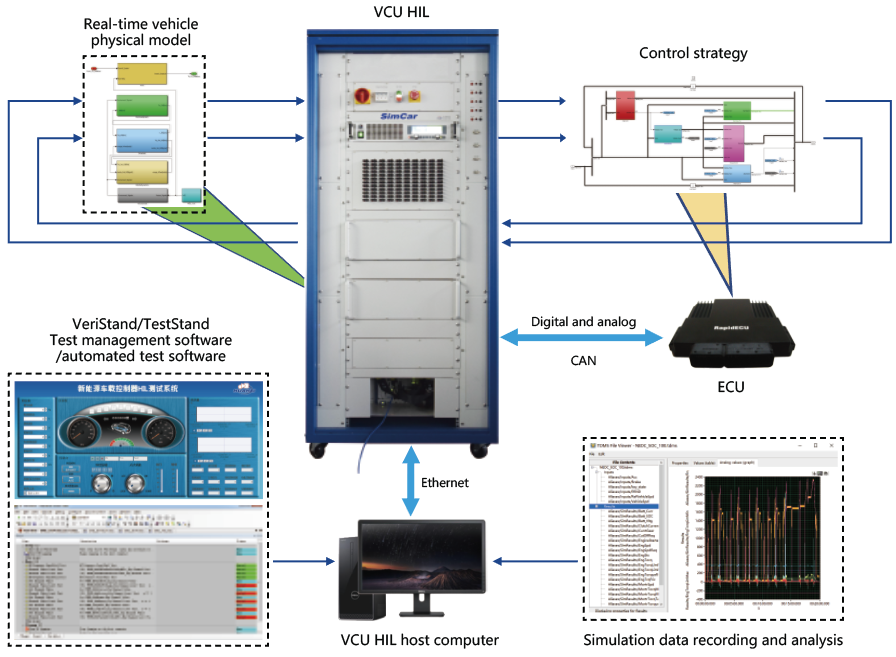

VCU-HIL system architecture

VCU-HIL system architecture

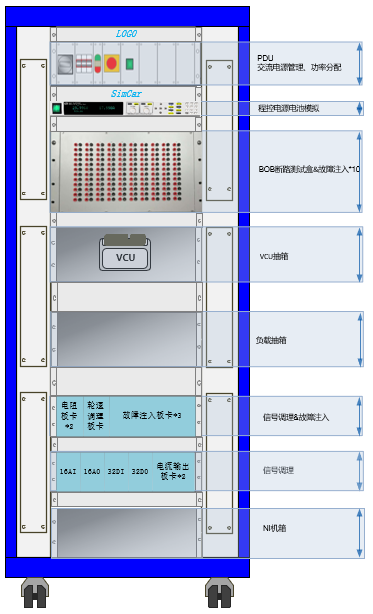

♦ Hardware Simulation Platform

• NI chassis (RT real-time system, real-time processing board, IO board)

• Signal conditioning unit

• Function conditioning unit

• Open circuit test unit

• Fault injection unit

• Load simulation unit

• Programmable power supply

• Power distribution unit

• Connectors, wiring harness

• Cabinet

• Host computer system hardware |

|

♦ Real-time Simulation Model

The real-time simulation model simulates the vehicle object controlled by the VCU. It can simulate the running state of the vehicle in real time through the implementation of the processor, and exchange information with the VCU through the IO channel, so as to conduct a comprehensive and systematic test on the VCU.

Features of real-time simulation model:

• The entire vehicle model runs in the real-time system, and the overall solution step length is ≤1ms, which can meet the real-time requirements of the VCU hardware-in-the-loop test system;

• The vehicle model is built based on Matlab/Simulink and supports secondary development. Users can use custom modules to replace standard modules in the original model;

• The simulation model files are delivered in a white box, using physical modeling to display the lowest level library modules, and the model does not contain any S-function package;

• The model is completely open source, all models can be edited, modified, and set parameters, and users can configure their own parameters;

Real-time simulation model composition:

Whole vehicle physical model structure

Whole vehicle physical model structure

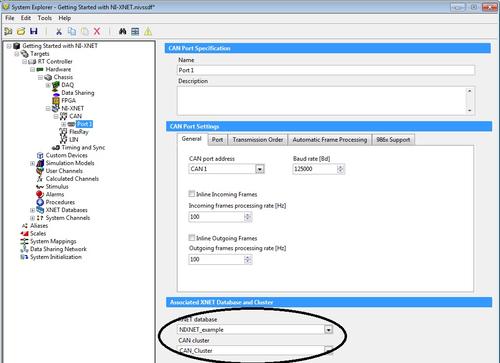

♦ Test Management Software

VeriStand features:

• Realize system configuration management and test management;

• Graphical interface design, which can realize the data connection between the to-be-observed/changed data and the GUI in the form of mouse dragging;

• Support real-time monitoring of CAN signals, realize model and CAN bus communication, can import corresponding application layer protocol (DBC file), and debug CAN communication;

• The input/output interface list of each software and hardware module can be clearly displayed in the interface, and the data connection between the software and hardware modules can be quickly realized;

• The compiled model can be deployed to the real-time machine, data observation and parameter changes can be performed in real time, and the simulation data can be saved;

VeriStand configuration interface

VeriStand configuration interface

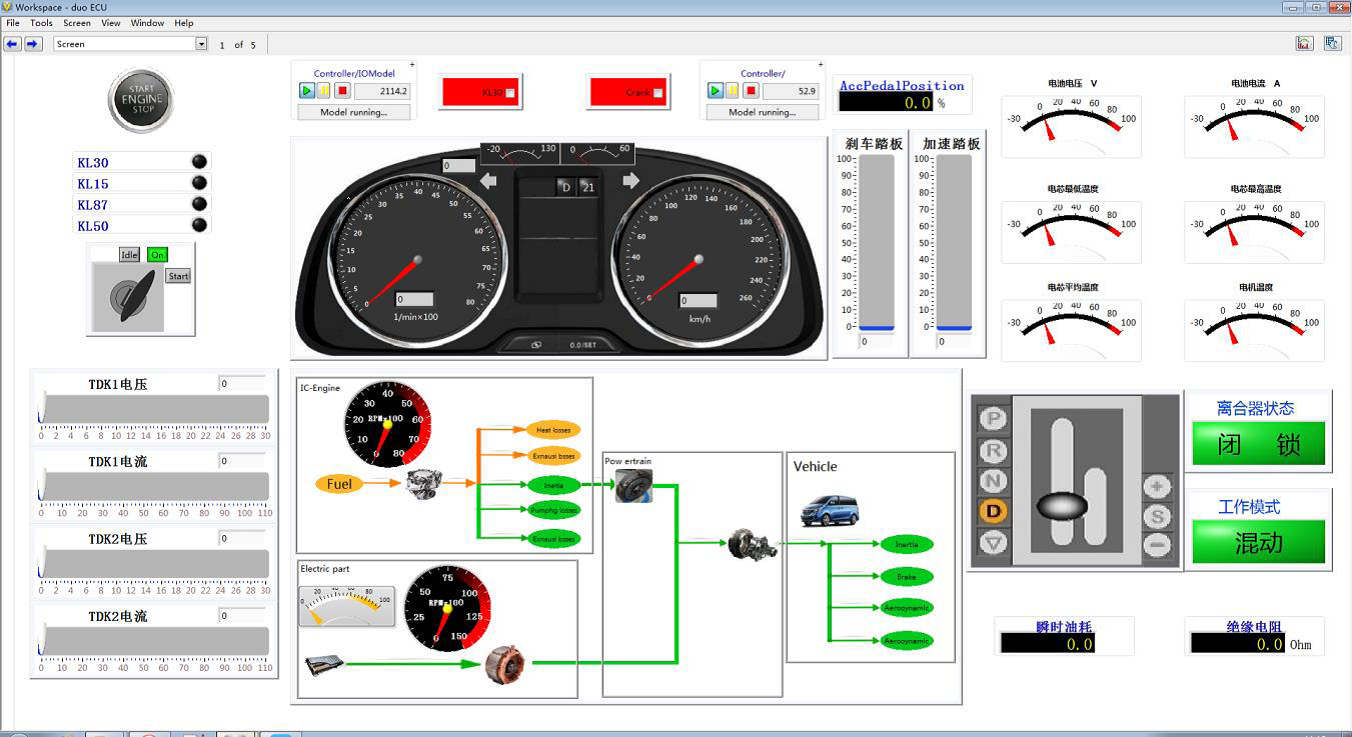

Test interface for hybrid electric vehicles

Test interface for hybrid electric vehicles

Test interface of pure electric vehicle

Test interface of pure electric vehicle

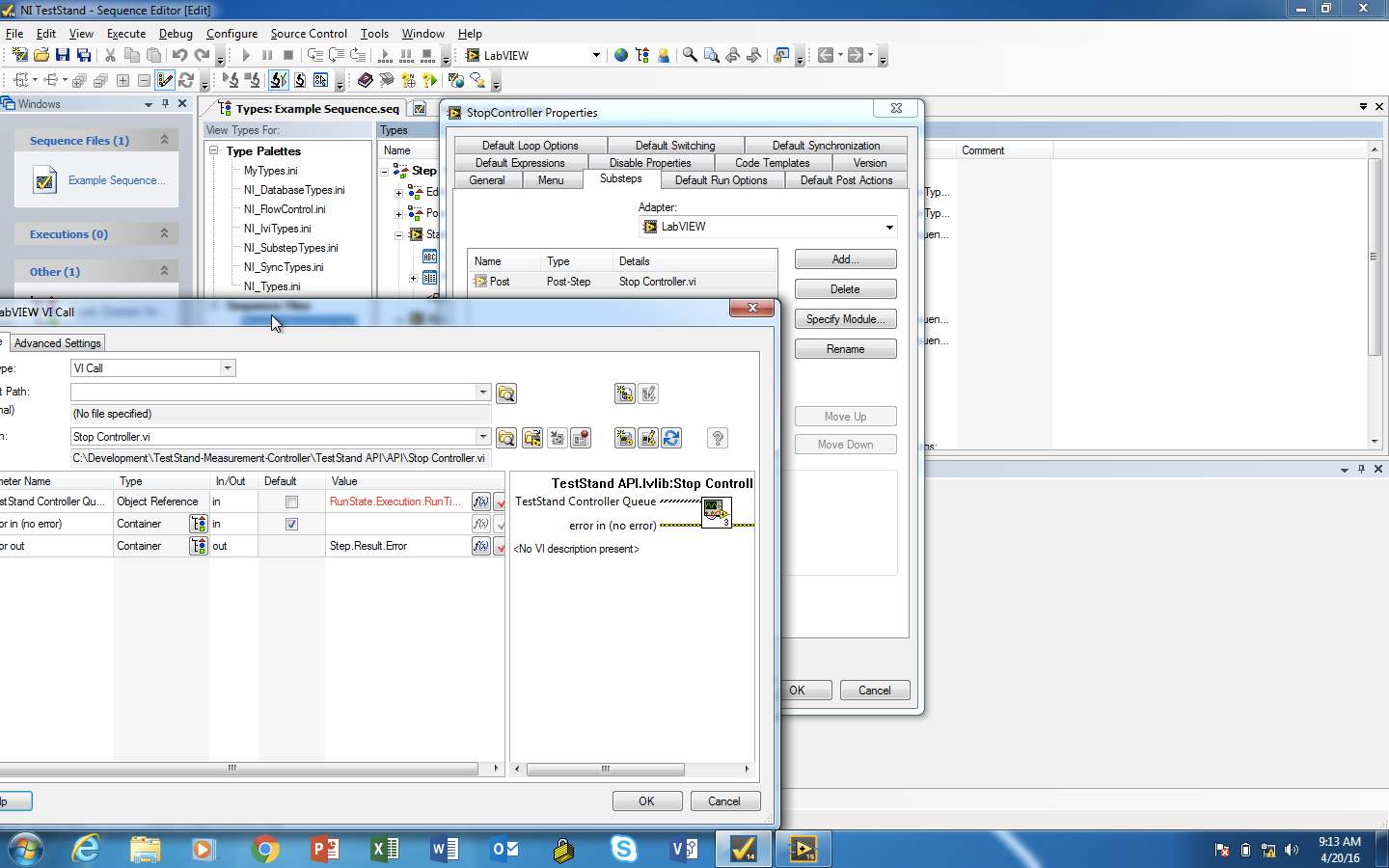

♦ Automated Test Software

Automated test software can easily integrate independent test modules into the same test framework; through this easy-to-integrate feature, developers can focus on the development of test programs instead of spending too much time on the tests required to build a test system frame.

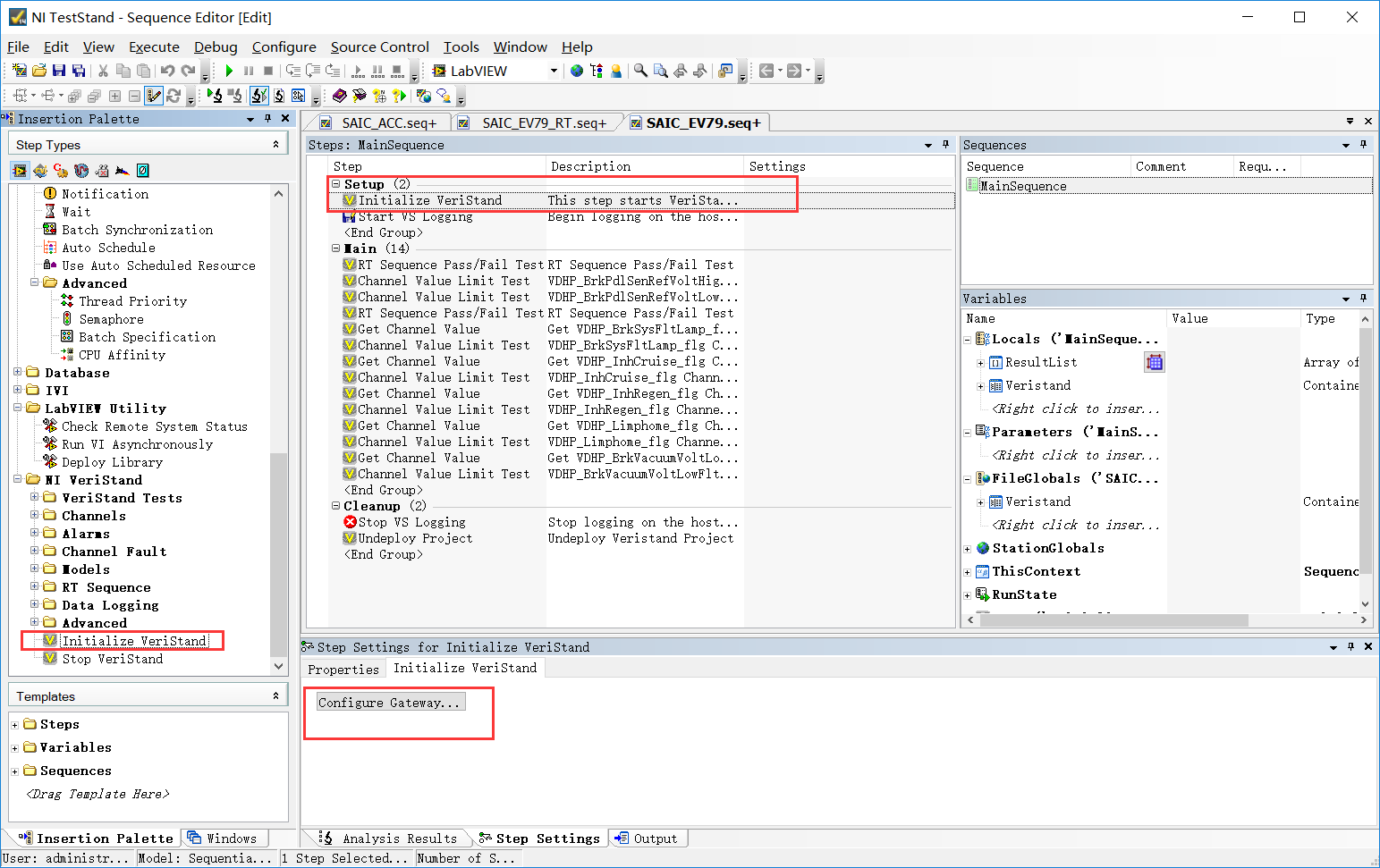

Automatic test software interface

Automated testing software function:

• Visual test sequence editing environment, supporting the use of graphical drag and drop to build test sequences and test cases;

• Test management function, seamless connection with test management software can automatically open test management software for model deployment;

• Realize test case library management, test parameter management, and test sequence management;

• Test report management, which can automatically generate test reports based on XML in HTML format.

HTML format test report |

Test case configuration interface |

—— Typical Case

|