|

|

|

—— Electronic Control System Of High Pressure Common-Rail Diesel Engine

High pressure common rail diesel injection system can realize the flexible control of fuel injection pressure, injection pulse width and injection timing. It is the preferred fuel system for electronically controlled diesel engines to meet the National IV and above emission standards. At the same time, the high pressure common-rail diesel engine also has significant fuel economy and strong power performance.

Based on RapidECU rapid development solution for high pressure common rail diesel engine ECU, users can complete the development of high pressure common-rail diesel engine ECU prototype within a few weeks, realize the basic working conditions of engine starting, idling, acceleration and deceleration, complete the development of mass product samples within a few months, realize the small and medium-sized batch loading, and lay a good foundation for the mass industrialization of high pressure common-rail diesel engine ECU.

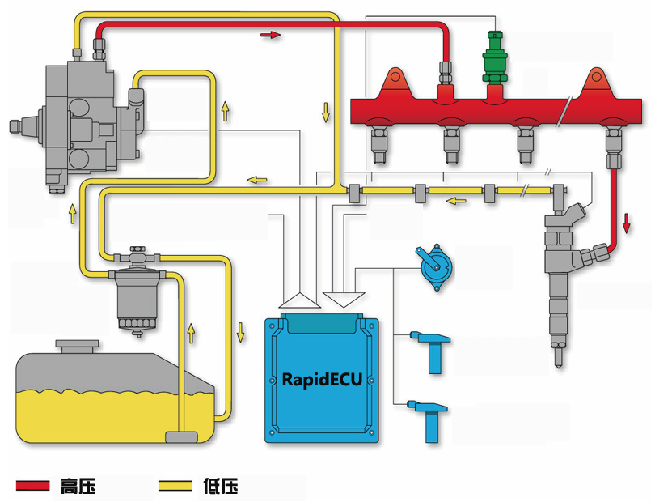

Composition of electronic control system for high pressure common-rail diesel engine

Composition of electronic control system for high pressure common-rail diesel engine

Basic Functions:

• Engine start and idle control

• Multi injection control, Complex injection waveform control

• Rail pressure control, Smoke limit function

• Torque control, Adaptive control of transition conditions

• Cooling fan control, Preheating control

• Engine speed limit function, Exhaust temperature protection

• Variable section turbocharger control

—— Alternative Fuel Engine Management System

In the face of the rising oil price and more and more stringent emission regulations around the world, major engine plants and research institutions are committed to the development and research of alternative fuel engines with higher thermal efficiency, economy and low emissions.

Through the research and analysis of the latest trend of alternative fuel engine technology and industrial development, combined with our company's technical advantages in the field of engine control and development of test platform resources, we provide customers with alternative fuel engine management system development turnkey engineering solutions, which are suitable for automobile, ship, engineering machinery, energy and power industry users.

Composition of typical application system:

Mainly for the following engine types:

• Natural gas - diesel hybrid fuel engine

• Methanol \ ethanol-gasoline hybrid fuel engine

• LNG\CNG\LPG engine

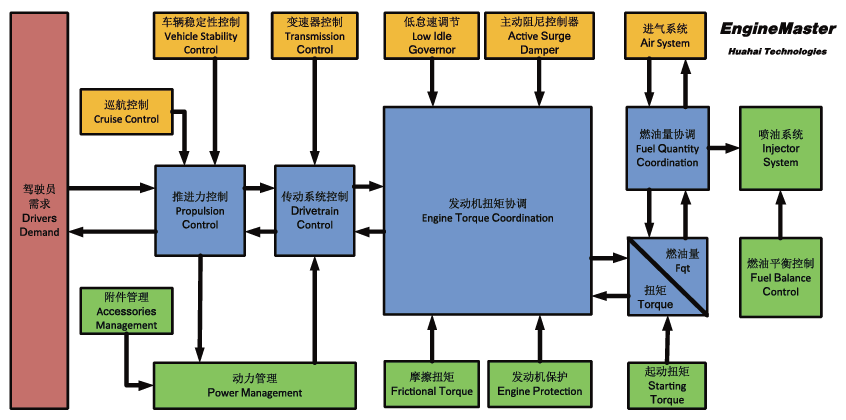

Model architecture of high pressure common-rail control algorithm based on torque

Model architecture of high pressure common-rail control algorithm based on torque

—— Classic Case

Rapid prototype development of energy saving control

strategy for medium sized excavator engine

|

Marine dual fuel engine control strategy development

|

Development of control strategy for high pressure

common rail diesel engine

|

Development of control strategy for Lin / diesel

dual fuel engine

|

|

|

|