|

|

|

—— Overview

MeCa is a general-purpose ECU measurement&calibration tool, which can collect and display ECU internal data in real time, and simultaneously adjust ECU internal parameters online. In addition, MeCa also provides automatic measurement and calibration functions, ECU program flashing and upgrading functions, etc. MeCa supports CAN-based calibration protocol CCP, and communicates between upper and lower computers through CAN bus. MeCa provides a fully graphical user interface and a variety of graphical controls, which can display various styles of measurement data and adjust calibration parameters.

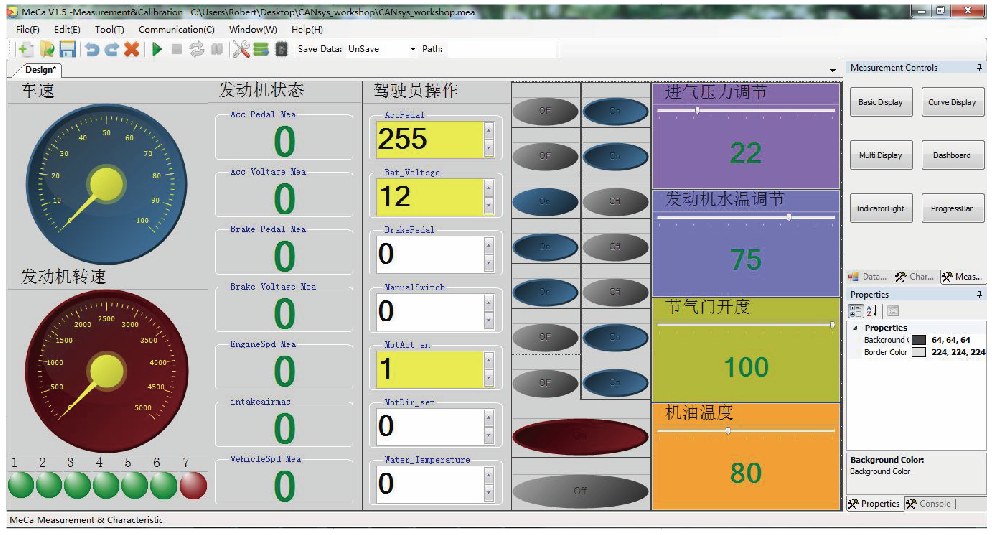

MeCa measurement&calibration software interface

MeCa measurement&calibration software interface

—— Main Function

• ECU internal data collection and monitoring

Provides a series of rich graphical controls such as curve oscilloscope, thermometer, tachometer, digital display, indicator light, etc., which can conveniently observe the changes of ECU internal data in real time.

• ECU real-time calibration

Provides calibration controls such as switches, knobs, curves, 3D MAP, and can access and modify RAM and Flash data for real-time online calibration.

• ECU flashing

One-click to complete the flashing and updating of the ECU internal program, and to ensure the accuracy of the code flashing through the handshake program, and the flashing is convenient and quick.

• Data storage and analysis

The recording and storage function can store the measurement data in the upper computer, and save it in data formats such as CSV. The stored data can be calculated and analyzed through MeCa, and the data can also be imported into MATLAB and other powerful mathematical operation software for post-processing.

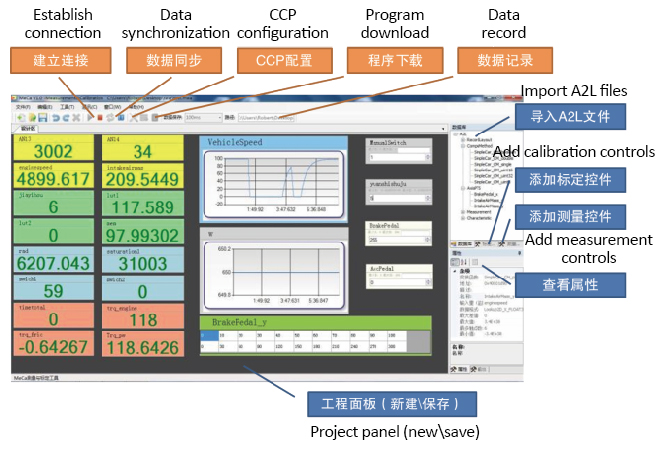

Software interface function introduction

Software interface function introduction

—— Main Advantage

• Data measurement and parameter calibration are carried out simultaneously.

• The software design is simple and easy to use.

• Provide a variety of graphical controls for easy observation and modification.

• Can export measurement files in common format.

• Automatic measurement and calibration and generate result documents.

• ECU program flashing and upgrading.

—— Measurement&Calibration System

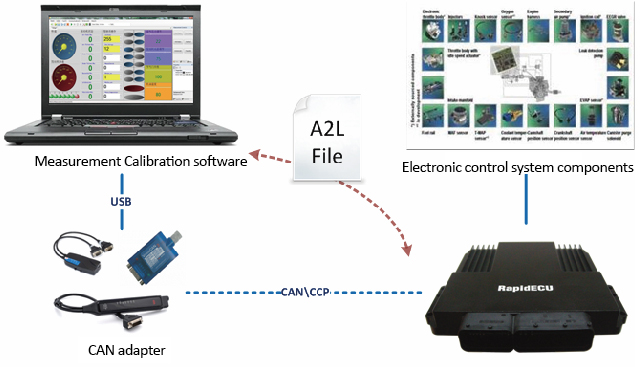

MeCa software supports CCP calibration protocol based on CAN bus, supports automotive-grade professional CAN communication interface hardware; supports importing standard A2L files. MeCa communicates with the ECU through the CAN adapter, and realizes the measurement and calibration of the internal variables of the ECU based on the CCP protocol and the corresponding A2L file, thereby controlling the collection of sensors and the execution of the actuators.

Schematic diagram of measurement calibration system

|