|

|

|

—— Overview

Facing the development of various complex electronic control systems, we need to select and build the development platform first. We have customized a complete set of model-based and goal-oriented electronic control system development tool chain-- RapidECU controller rapid development platform for you, including all the software and hardware needed to establish and start the control system development.

You only need to choose the most suitable hardware platform among a series of standardized and highly reliable hardware platforms that we have prepared for you according to the different requirements of the control system application.

All the software provided by the development kit adopts driver free USB Encryption license, which can be used in any computer hot swap without setting any controller hardware binding.

—— Main Features Of RapidECU

※ The new controller is equipped with the latest 32-bit automotive electronic professional chip

The controller core is equipped with the latest generation of qorivva MPC55xx / 56xx / 57xx 32-bit processor chip of Freescale, Also support Infineon TC275, 387, and TI DSP28XXX series, which greatly improves the storage operation ability and cost performance.

※ Special hardware functions for more convenience

Especially for the special needs in the development of new energy vehicle controller, battery management system, motor controller, automatic transmission, in cylinder direct injection gasoline engine and high-pressure common rail diesel engine control system, it improves the universality of the platform and the convenience of users.

RapidECU integrates the interface resources needed for signal conditioning, power drive, communication, calibration, diagnosis and brush writing of various vehicle control systems. It can meet the application requirements of various vehicle electronic electronic control systems without the user's external connection or remaking the drive board.

※ From rapid prototyping to mass production, the hardware is solid and reliable, and the environment is adaptable. It can be fully customized for mass production

RapidECU hardware is safe and reliable, and can be used for mass fleet testing even in the most demanding environments. The hardware has been professionally designed to meet the stringent automotive and defense requirements.

For rapid prototyping, trial production and small and medium-sized batch production have higher cost-effectiveness. Because the main circuits and software of rapidecu adopt reusable modular design, even if the unit cost is to be further reduced in mass production, it is very convenient to tailor unnecessary resources and develop an ECU for OEM mass production.

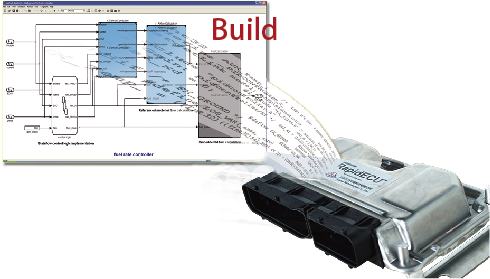

※ Using automatic code generation technology

Simulink model can automatically generate source code and compile executable code without any manual programming. After the compiled S19 program file is downloaded to RapidECU, the real-time operation of Simulink model algorithm in the controller hardware is completed, and the real-time online calibration of calibration variables can be realized in the early stage of product design.

Automatic code generation

Automatic code generation

※ The code is completely open-source and directly serves as a reference for product design

The source code of product level hardware based on rapidecu is all open, and the code of product and prototype stage is reused. Thus, for users who want to independently develop the controller based on the same chip, the product level source code of RapidECU can be used as an important reference or directly for industrialization.

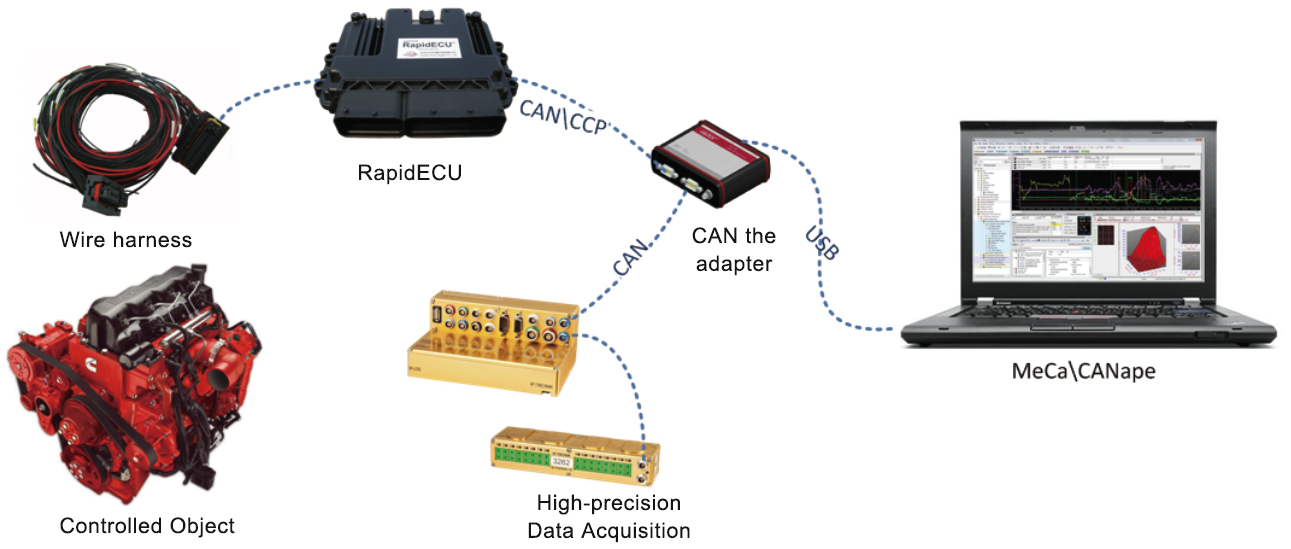

※ Adopt asap2 standard CCP calibration protocol

The standard A2L file is automatically generated. After simple setting, various common calibration tools (such as MECA, Inca, canape, vision, etc.) can be used for real-time online calibration of RapidECU.

Calibration system connection diagram

Calibration system connection diagram

—— Application Field

• Fuel cell engine controller FCU

• Hybrid / pure electric vehicle controller HCU / VCU

• Automatic transmission TCU

• Motor controller MCU

• Battery Management System BMS

• Chassis electronic control device EPS / EPB / ESP / ABS

• ECU of high pressure common rail diesel engine

• GDI / PFI gasoline engine ECU

• ECU of LPG / CNG / LNG engine

• Control unit of SCR / DPF tail gas after treatment system

• Hydraulic system control unit

• Various other automotive electronic control systems

—— Installation and Running Environment

Hardware Requirements:

CPU:double core and above

Memory: 2G and above

Hard disk space: 10G and above

Software Requirements:

Operating system: Windows XP/Vista/7/10, 32-bit or 64-bit versions

Compiler: CodeWarrior 2.9 or above, S32 Design Studio

MATLAB version: R2010a above 32-bit or 64-bit Windows version

The Mathworks Software:

• MATLAB

• Simulink

• Embedded Coder

• Simulink Coder

• MATLAB Coder

• Stateflow

RapidECU controller rapid development platform

|