|

|

|

—— Overview

The durability test bench is mainly combined with environmental test equipment(temperature and humidity box、vibrating table、salt spray box、spray box etc endurance test auxiliary test equipment) then according to the endurance test ISO16750 (which includes high and low temperature test、vibration test、voltage test、waterproof and dustproof test、safety and service life test etc ) to endurance(DV/PV) test for the controller under test. The endurance test bench provides excitation、load simulation、no-load simulation etc virtual operating environment, Make the sample to be tested run in accordance with the established test conditions, Simultaneously collect the voltage、current etc signal; The enduring test upper computer provides the operating time sequence of the controller under test, And Real-time monitoring and recording of the signal status、error and alarm Information etc, Finally, The test report is automatically generated. This durable bench test system supports parallel testing of multiple tested controllers, Generally based on NI-PXI platform and LabVIEW software development.

Huahai Technology provides a low-energy environmental friendly, safe and reliable durable test bench and test software, Convenient for durability test and performance test of various controllers and parts.

—— Test System Capabilities

• Durability test up to 2000 hours;

• Simulation of controller operating conditions;

• Support multiple UUT parallel testing;

• Support CAN and UART programming;

• Modular design idea, with good expansion function.

—— System Functions

• Mobile phone remote monitoring function;

• MES online and local data storage;

• Database backup function;

• Data statistics and analysis functions;

• Automatic test report generation function;

• DUT timing simulation and diagnosis function;

• CAN frame loss diagnosis function;

• CAN function test;

• LIN frame loss diagnosis function;

• LIN function test;

• Automatic fault prompt and alarm output function;

• Ethernet message test function;

• Test program online programming function, support data files in BIN, HEX and other formats;

• BOOT programming function(support TI series and Infineon series chips temporarily);

• Log management function;

• Electrical fault test such as short circuit, open circuit and poor contact;

• Equipment self-check function;

• Secondary development function;

• DUT input and output test function. |

—— System Structure Diagram

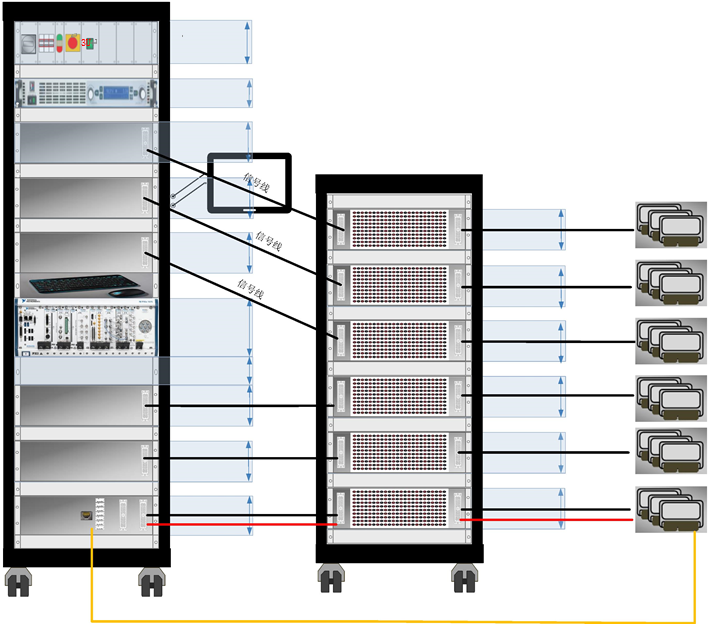

#6VBU/#6BMU Structure diagram of durability test system

#6VBU/#6BMU Structure diagram of durability test system

Mainly include the following parts:

• AC power management, power distribution unit;

• Programmable power supply;

• Power distribution unit;

• Fault injection unit;

• Ethernet interface unit;

• Load box;

• PXI real-time machine;

• Signal conditioning unit;

• Fan cooling unit;

• The controller under test.

—— Classic Case

#6 DUT parallel operation system physical map

#6 DUT parallel operation system physical map

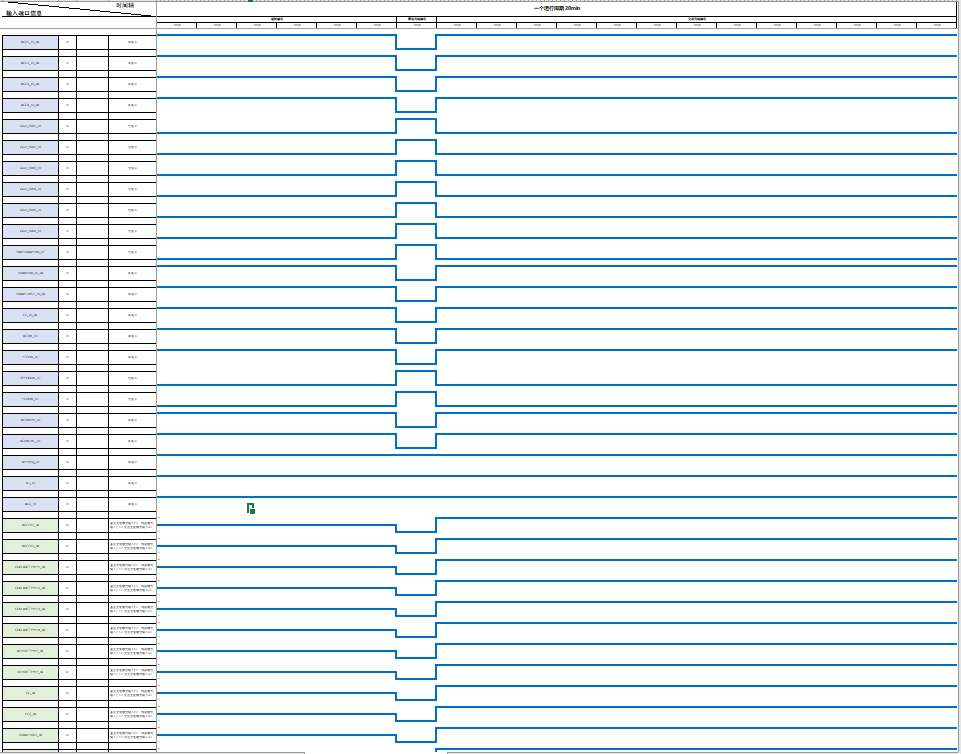

Output conditions of time sequence diagram

Output conditions of time sequence diagram

Input conditions of time sequence diagram

Input conditions of time sequence diagram

Schematic diagram of test site

Schematic diagram of test site

|