|

|

|

| Huahai assists the world premiere of Hanhe Automobile Xingsu |

In June 2020, Guangzhou Hanhe Automobile cooperated with Huahai and signed the development project of Hanhe Automobile's first hydrogen fuel cell powered intelligent driving truck vehicle control development project. Within a few months, the Huahai technical team and the Guangzhou Hanhe Automotive technical team worked together and almost perfectly completed the opening day of the 2020 UNDP (United Nations Development Programme) Hydrogen Energy Industry Conference. Hanhe Automotive brought Xingsuo 1 World premiere.

During this research and development process, Huahai Technology provided the complete vehicle controller hardware, bottom layer and application layer software, completed the system scheme design, software function realization and unit testing, software and hardware integration and testing, and completed the road test and the actual vehicle. Calibration: The vehicle realizes functions such as high-voltage power-on and power-off, torque management, mode management, energy management fault diagnosis and protection, and at the same time realizes fuel cell start-stop control, power point switching control and automatic driving mode switching control.

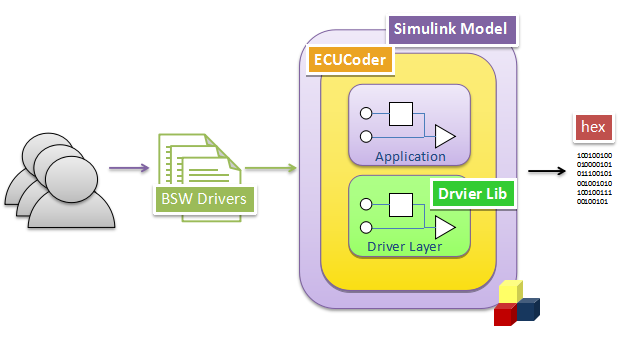

The controller development process adopts a model-based V-shaped development model, uses MATLAB/Simulink to establish a software control project in graphical modeling, and uses the company’s self-developed ECUCoder one-click automatic code generation tool to implement application software (ASW) and Automatic code generation for basic software (BSW) models.

ECUCoder is a fully automatic code generation tool based on Simulink, used to configure ECU control algorithm models and basic software models, and automatically generate product codes. Support mainstream chips for automotive electronic control systems from well-known manufacturers such as Freescale, Infineon, and ST. ECUCoder provides a powerful basic software Simulink module library, which can conveniently and intuitively configure basic software parameters through a friendly user interface and automatically generate basic software codes from Simulink models. Because the software can flexibly and deeply access and configure basic software parameters, the basic software code generated by the model can support the two stages of controller rapid prototyping and product development.

The core value of ECUCoder is to shorten the development time of several months of controller basic software to several hours.

The main features of ECUCoder:

• Automatic code generation of basic software and application software at the same time, without manual integration;

• The model automatically optimizes the configuration, no need to manually set Simulink configuration parameters;

• Powerful GUI interface, which can directly access and configure the entire basic software from the model;

• The compiler is automatically invoked in the background without manual intervention;

• Reliable code, good compromise between code readability and execution efficiency;

• Support the latest generation of multi-core processors that meet the ISO26262 standard, and support user-developed controller hardware.

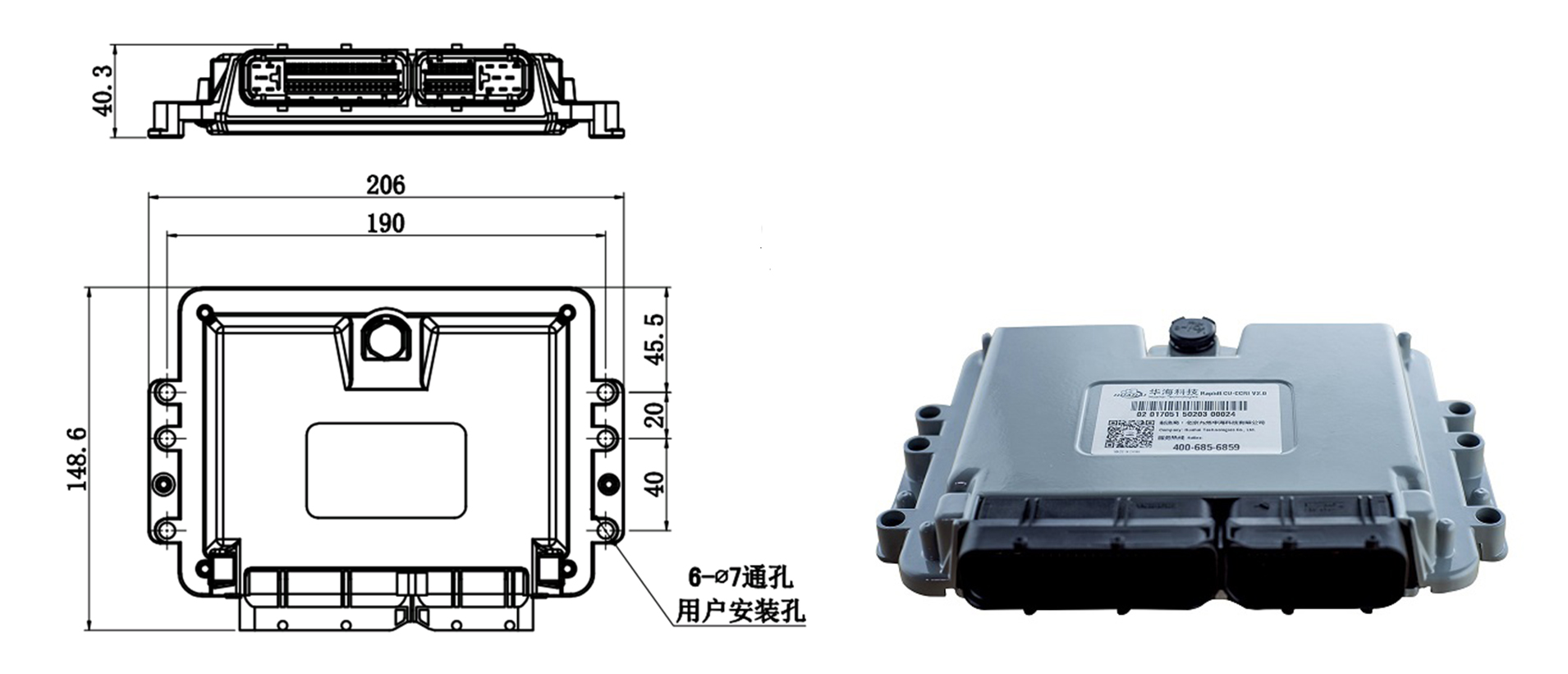

The vehicle controller hardware RapidECU-F2 provided by Huahai Technology is a new generation of mass-produced electronic control unit that supports rapid prototyping and batch supporting of the vehicle controller VCU, hybrid controller HCU, thermal management system TMS, etc. The definition, design and verification of products are all carried out in accordance with the ISO26262 standard.

|

Basic parameters |

|

Micro controller |

SPC5743R, 32-bit, dual core, Max. 200MHz, hardware floating-point unit, ISO26262 |

|

SRAM 128KB,Flash 2MB,FRAM 64Kb |

|

Power supply |

9V~32V,3 external hard wire wake-up signal |

|

4-channels of 5V sensor power supply, 2-channels of 12V sensor power supply |

|

Input |

24-channels of analog input, including 10-channels of resistance input (passive sensor), 2-channels of 0~12V voltage input, 22-channels of 0~5V voltage input (including 10-channels and resistance input multiplexed pin) |

|

22-channels of switching input, including 16-channels of high-effective switching input and 6-channels of low-effective switching input |

|

6-channels of PWM frequency input, support signal frequency measurement and pulse width measurement, frequency range of 10Hz~15kHz, high level voltage range of 3.3V~32V |

|

Output |

5-channels of Peak-Hold bilateral drive (two pin in each channel), supporting BOOST, diode with continuous flow, supporting PWM and switching modes, Peak 1~7A, Hold 1~3A, software configuration of Peak-Hold current value |

|

15-channels low side drive: 1-channel rated current 0.7A, switch operating mode; 5-channels rated 4A, peak value 8A, with continuation current diode, support PWM working mode and switch working mode, support current feedback; 6-channels rated 0.4A, peak value 0.8A, switch operating mode; 2-channels rated 0.4A, peak 0.8A, with continuous flow diode, supporting PWM and switching working modes; 1 channel rated 1A, peak 3A, support PWM operation mode and switch operation mode |

|

6-channels high-side drive, rated 1A, peak 3A, support PWM operating mode and switching mode (among which 2-channels and H-bridge power drive output multiplexed pin) |

|

Power drive output of 2-channels H-bridge, rated 1A, peak 2.8A |

|

Communication |

4-channels CAN, CAN2.0b, ISO11898, 3-channels with 120R terminal resistance, 1-channel without terminal resistance |

|

Environment |

Protection class: IP67, working temperature: -40℃~+105℃

The protection of climate and environment conforms to ISO16750-4 and the protection of chemical environment conforms to ISO16750-5

Vibration, impact and drop tests conform to ISO16750-3 |

|

EMC features |

|

ESD |

Air ELECTROSTATIC discharge test and contact electrostatic discharge test meet the relevant requirements of ISO 10605-2008 |

|

BCI |

Electromagnetic radiation immunity conforms to the relevant requirements of GB/T 17619-1998 |

|

CE |

The related requirements of conducting disturbance are in line with 2008f GB/T 18655-2010 |

|

RE |

Radiation harassment complies with the relevant requirements of GB/T 18655-2010 |

|

CI |

The transient conduction immunity along the power line conforms to the relevant requirements of ISO 7637-2:2004 |

|